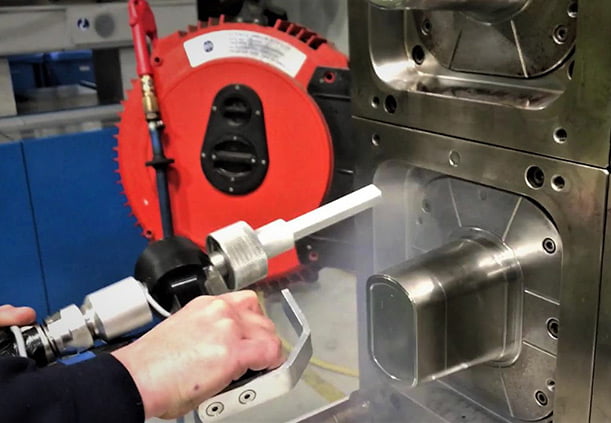

Dry Ice Blasting in Plastic Injection Moulding

Dry ice blasting is versatile and effective for cleaning various substances and materials, including:

– Release agents

– Overspray

– Hardened plastic

– A combination of all used materials and substances

The advantages of using dry ice blasting in the plastic industry are numerous:

Mold Preservation: Dry ice blasting preserves the integrity of the mold, resulting in a longer mold lifetime and reduced costs.

Dry ice cleaning is highly advantageous for cleaning molds, screws, mixers, and other equipment in the plastic and styrofoam injection industries. It offers a multitude of benefits in these applications, such as efficiency, environmental friendliness, and the preservation of equipment integrity.

Performing on-site cleaning without the necessity of removing molds from the plastic injection molding machine offers several advantages. Cleaning while the equipment is hot is a notable benefit of dry ice cleaning, allowing for a swift return to production without the need for cooling and reheating.

What might typically consume hours can now be accomplished within mere minutes.

Frequent cleaning not only reduces the duration of each cleaning operation but, more importantly, it also minimizes reject rates to the bare minimum.

Achieving a superior finish and quality is possible without the use of dust, water, or chemicals.

Labor Cost Reduction: Reduced labor requirements for cleaning processes. Surface Protection: It prevents damage to the finished product surface, thereby lowering waste and scrap rates.

Dust-Free

Dry ice blasting leaves no dust behind.

No Water Residue

No water residue or moisture left on the cleaned surfaces.

On-Site Cleaning

Cleaning can be conducted in the same location, minimizing downtime and transportation costs.

Efficiency

Dry ice blasting cleans slots and screen vents simultaneously, ensuring thorough cleaning.

Dimensional Stability

Maintains mold surface dimensions without any alterations.

Lower Rejects

A 100% clean mold results in fewer rejected products.

Cleaning the Unseen

It effectively cleans areas that may not be readily visible or accessible.

Outstanding Industries

We provide detailed insight into the benefit of cleaning with dry ice for the many industries

where dry ice is the preferred cleaning method.